|

|

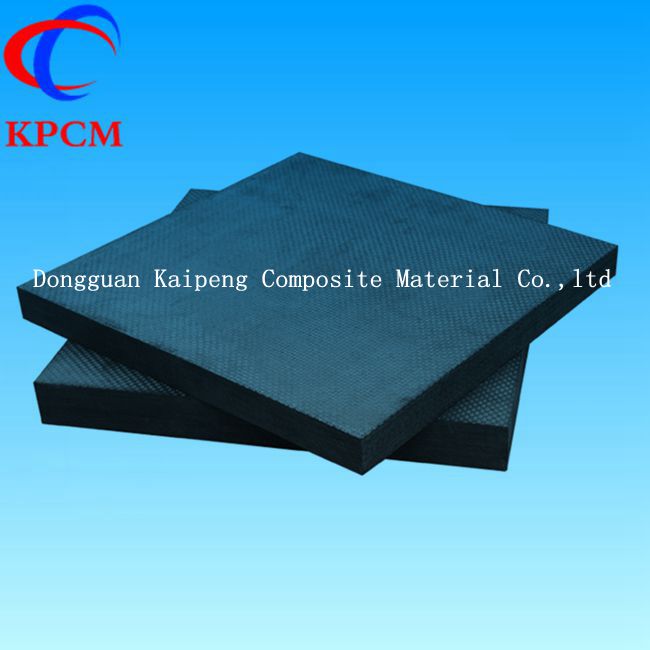

C/C composite material introduction and performance characteristics C/C composite material introduction and performance characteristics Carbon carbon composite material, is based on carbon or graphite fiber and fabric reinforced material, carbon (or graphite) as matrix, through processing and handling all the carbon composite material made of carbide

C/C composite material profile English name:c-c composite or carbon-carbon composite material,is based on carbon or graphite fiber and fabric reinforced material, carbon (or graphite) as matrix, through processing and handling all the carbon composite material made of carbide.It originated in 1958, the United States for laboratory accident Chance - Vought company, than when carbon fiber resin matrix composite curing temperature, resin carbonized form c/c composites C/C composite material is carbon fiber reinforced carbon composites, light quality, good erosion resistance, good thermal shock, high damage tolerance, high temperature and high strength, can be designed as a prominent feature, is used in aviation, spaceflight, circuit level and the production of solar energy silicon, high temperature furnace and other applications

C/C composite material performance characteristics Physical properties: C/C composites at high temperature after heat treatment, the chemical composition of carbon element is higher than 99%, low density, with strong affinity, high melting point, due to carbon with high temperature resistance, corrosion resistance and thermal shock performance of good features, acid, alkali, salt Mechanical properties: reflect the mechanical behavior of C/C composites is strength and modulus of elasticity, resistance to friction and wear performance is good High temperature stability: C/C composites at room temperature strength can keep up to 2500 ℃, is not sensitive to the thermal stress, ablation resistance performance is good Comprehensive performance evaluation: C/C composites at room temperature strength and elastic modulus, good production C/C composites link, saves materials and manufacturing cost, safety and high reliability

C/C composites manufacturing technology In the choice of technology to the preparation of C/C composites, should according to the requirements of the C/C application first choose to use what kind of fiber and matrix, and then determine the preparation of fiber and matrix material to use Carbon fiber preparation technology: the preparation of carbon fiber using different raw materials, the process is slightly different. If use polyacrylonitrile, acrylonitrile polymerization, spinning, used as flame treatment, carbonization, eventually forming products. If use asphalt, coarse asphalt refining, melt spinning, the final carbonization. The quality of C/C first depends on the quality of carbon fiber Weaving technology: weaving techniques can be divided into one-way weaving and knitting garment. Weaving for at least 2 to garment, to up to 11. Also can be divided into machine weaving and knitting. And subdivided into radial knitting machine and weft knitting. Machine knitting technology was unable to get their products fluff or break easily and widely used; Hand-woven technology because of its product does not exist the faults of knitwear and widely used at home and abroad. Currently use more is wound by hand woven and cross weaving, more advanced weaving is targeted Dense technology: after forming fabric or textiles for the densification process. Dense technology is divided into liquid impregnation, solid immersion and gas impregnation technology. The current application more is chemical vapor deposition technology The development of the technology: chemical vapor infiltration process, computer simulation, the C/C composites density technology, carbon/carbon technology

|